In the demanding, high-efficiency world of air cargo, effective ground operations are an undeniable necessity. Our ULD Racking Systems are the engineering-designed backbone of a modern cargo terminal.

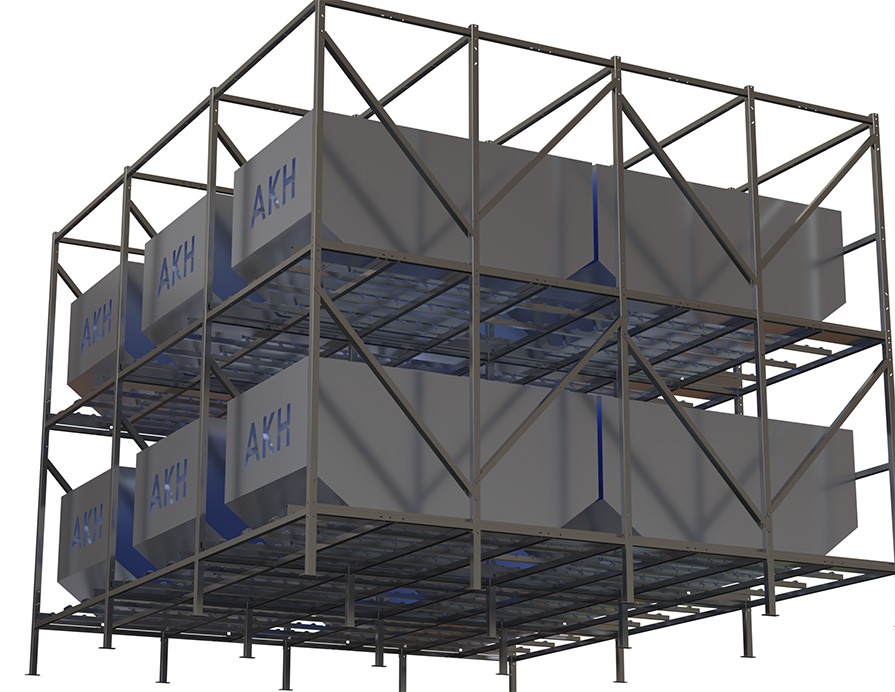

These systems, specially designed for the safe storage and retrieval of Unit Load Devices (ULDs) such as pallets and containers, transform your vertical space into an organized, high-access storage area.

This approach significantly increases storage density, freeing valuable floor space for dynamic processing and handling operations. Beyond optimizing space, our rack solutions are built with heavy-duty structural steel and advanced safety mechanisms to ensure the safe, collision-free movement and storage of fully loaded ULDs. We offer fully integrated solutions that seamlessly connect with automated systems—or they can also be provided as standalone static structures. Each system is custom-designed to match the unique dimensions of your facility and its operational throughput requirements.

Partner with us to ensure cargo integrity, accelerate operational flow, and elevate your facility’s safety standards.

ULD racking systems offer high-efficiency solutions that maximize storage density in air cargo terminals while accelerating operational flow. By ensuring the maximum use of vertical space, they free up valuable floor area and create a more organized, accessible, and safe structure within the terminal. Made from heavy-duty structural steel, these racks allow fully loaded ULDs to be moved and stored safely, significantly reducing collision risks and equipment damage.

Advantages

Advantages of

ULD Racking Systems

Provides maximum storage density

Efficiently uses vertical space to create significant space savings within the terminal.

Frees up floor area

Creates a wider and more organized working environment in the operational zone.

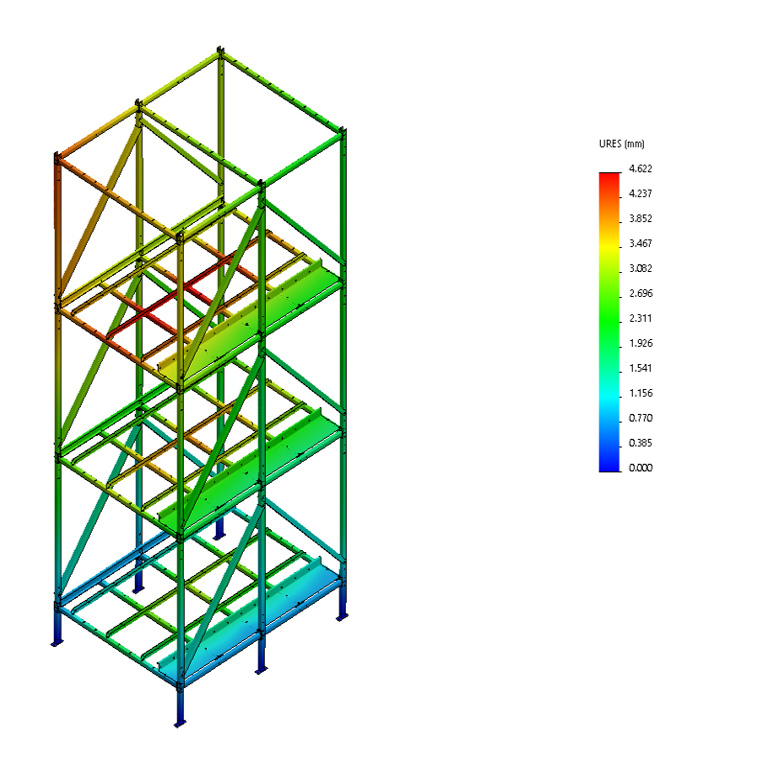

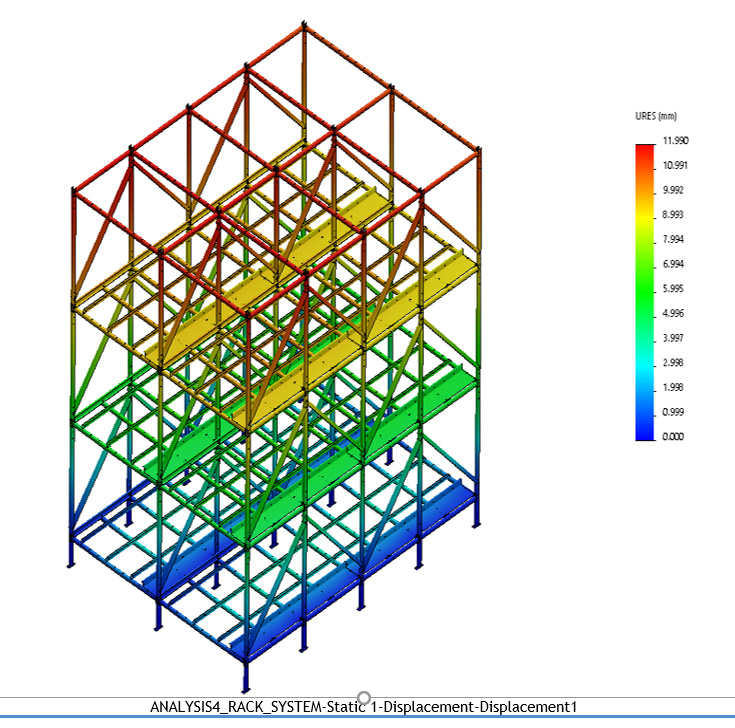

Offers high safety for heavy loads

Manufactured from robust structural steel that reduces the risk of collisions and falls for fully loaded ULDs.

Accelerates cargo flow

Enables fast, controlled, and easily accessible storage of ULDs.

Reduces equipment and container damage

Minimizes collisions and misplacements thanks to its engineering-based design.

Compatible with automation systems

Can be integrated with conveyors, transfer vehicles, and automated storage technologies.

Increases operational efficiency

Supports faster handling and more organized ULD management.

Enhances facility safety

Improves personnel and load safety through standard-compliant safety mechanisms.

Offers customization options

Can be specially designed according to the terminal’s dimensions, workload, and operational flow.

Long-lasting and durable

Provides years of trouble-free service thanks to its structure suitable for industrial usage conditions.