In logistics operations

the right and safe infrastructure

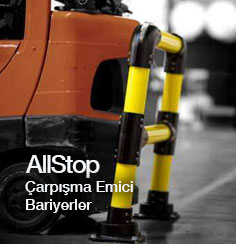

A new safety standard in industrial storage and air cargo systems! Allstop is an advanced safety technology for complete stop and collision prevention in warehouse and operational areas.

AllStop

Impact-Absorbing Barrier

Air Cargo

Solutions

Castor

Deck

Conveyor

Systems

Automated

Racking Systems